What are softwoods

Softwoods come from trees that are of the coniferous or evergreen species, such as pine or spruce. These species make up 80% of the world’s production of timber. Pine is used in our range of finishing timbers and decking products, Spruce for our structural and non-structural Carcassing timbers, and Fencing timbers. We can also offer Western Red Cedar and Larch for cladding and tongue and groove products.

What are hardwoods

Hardwoods come from leaf-bearing, deciduous trees, including ‘temperate’ species such Oak, Ash and Walnut as well as “tropical” species such as Sapele and Meranti. Through our extensive supply-chain we are able to offer hardwoods to suit all applications, from high-quality joinery, to decking, cladding and heavy structural applications.

Unsure of which type of timber you need? See our guide to the types of timber and common uses for them.

What are wood plastic composites

Wood plastic composites are a mix of recycled wood, recycled plastic and performative additives such as polythene (PE), polypropylene (PP), polyvinyl chloride (PVC) or polylactic acid (PLA). This combination of ingredients creates a material that is denser, stronger and longer-lasting than standard wood. This variation of timber is perfect for decking and landscaping purposes. Unsure about composite or wood decking? See our guide on the differences between wood and composite decking materials.

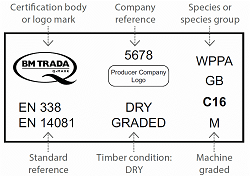

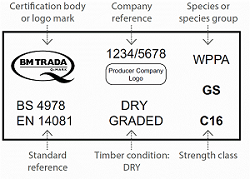

What are structural softwoods

Structural softwood is used where the timber is required for loadbearing purposes, for example, Joists or Roof members. Structural Softwoods in the UK fall mainly into 3 strength grades: C16, C24 and TR26 (which is specifically for Roof Trusses). The grade required will be based on both the cross section of the timber and the loadbearing put on it.

The strength of a piece of timber depends on a combination of the inherent strength of the timber species and the grade of the individual piece. A high grade of timber from a weaker species may be just as strong as a low grade of timber from a strong species. To make specifying easier, species and grades are grouped into strength classes of similar strength for softwoods, higher numbers indicate stronger timber.

C16 Span Tables

C24 Span Tables

What are timber sheet materials

Here at Jewson we understand the demand for a large range of sheet materials, we have added many specialist products to our branches to make sure you get the right timber sheet materials. Sheet materials have many applications from temporary flooring and walling to roofing and carpentry. We stock various sizes of door blanks, pin boards and notice boards, ‘Neat-match’ specialist MDF claddings and veneered MDF alongside more standard sheet materials like our handy panel MDF and Ply.

To find out more about sheet materials, check out our guide written by experts at Jewson!

More on sheet materials